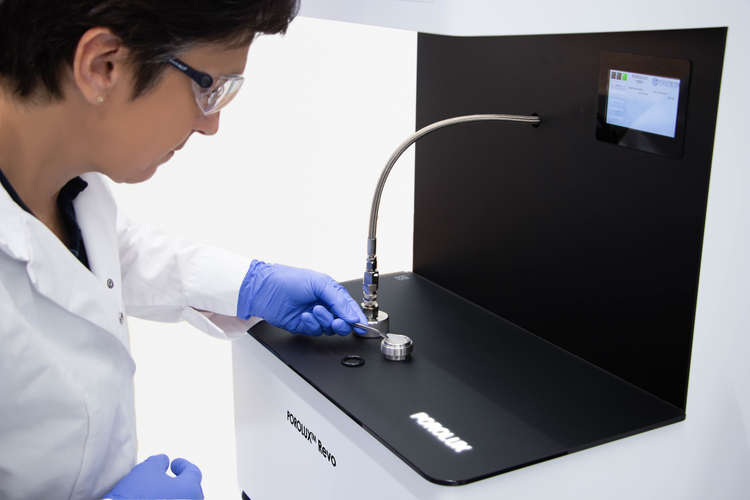

The POROLUX™ Revo, the successor of the POROLUX™ 1000, is the revolution in porometry. Setting the bar in step stability method with our patent pending MP² (Multistage Pressure Process) technology, the POROLUX™ Revo delivers the most accurate and reproducible pore size measurements, in the highest resolution.

Patent pending MP² technology

MP² stands for Multistage Pressure Process. This innovative technology ensures a smooth pressure increase during the measurement and speeds up the process of reaching flow and pressure stability.

This advanced pressure built-up process makes it possible to do the measurements with smaller, and perfectly uniform pressure steps, leading to the most accurate and reproducible pore size results. Additionally, the technology makes it possible to record more data points in the pore opening region, resulting in more detailed pore size distribution curves.

Step stability method

The POROLUX™ Revo detects the opening of a pore at a certain pressure and waits until all pores of the same diameter are completely opened before accepting the data point. This method results in a very accurate pore size measurement and allows to calculate the true pore size distribution.

Additionally, the instrument can determine the bubble point in three different ways (largest pore according to ASTM F-316-03), a very unique feature in the market of porometry.

Next to that, results on mean flow pore size, smallest pore, pore size distribution, cumulative flow distribution & gas permeability are reported. With our enhanced mathematical model, we can also obtain additional results such as total pore number and total pore area.

Very intuitive and easy to use software

Not only is the fully integrated software powerful and comprehensive, it is also very intuitive and easy to use.

By allowing to change many parameters with a click of the mouse, the software enables its many users to tune the measurement to their exact needs. Additionally, the software, with built-in intelligence, gives the user access to many advanced functions, such as the re-evaluation function and the observation window.

Last but not least, the POROLUX™ Revo software comes with a very advanced curve smoothing and fitting function.

Straightforward and presentable output

With one click of the button, results are exported in word, excel or pdf. The Porometer software makes it very easy to present multiple measurements next to each other, allowing for a straightforward comparison between different filter media.

Thanks to the adjustable scales, graphs such as wet and dry curve and pore size distribution are presented in a very clear and sophisticated manner.

Technical Specifications

| POROLUX™ Revo | ||

|---|---|---|

| Technique | Gas-liquid porometry | |

| Measurement method | Pressure step/stability with patent pending MP² technology | |

| Max pressure | 35 bar/500 psi | |

| Min pore (1) | 13 nm | |

| Max pore (1) | 500 µm | |

| Max flow | 200 l/min | |

| Bubble point | BP dPL, BP x-ml, BP pCF (*) | |

| Dimensions (DxWxH) | 530x530x755 mm | |

| Weight | 70 kg |

Accessories

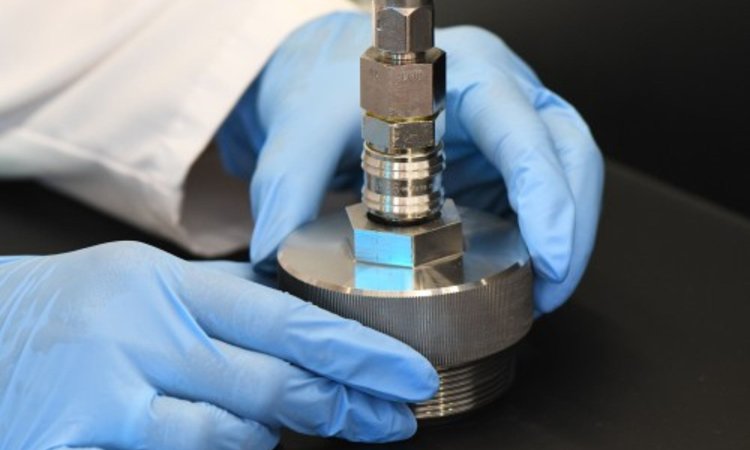

Vertical hollow fiber sample holder (picture)

Sample holder 3 diameters in 1 (13, 25 and 47 mm).

Hollow fibre sample holder

Specially designed sample holder for hollow fibres, including 5 sealant rings.

Sample holder of 25 mm diameter for thicker samples

External sample holder for samples of thickness up to 10 mm.

Customer specific solutions

Porometer can also create customer specific sample holders to meet special requirements, such as measuring thick samples, samples with larger diameters, working with assembled filter setups, etc.

Typical Applications

The POROLUX™ Revo is the right instrument to characterize a wide range of materials with complex pore structures, such as polymeric membranes (flat sheets and hollow fibers), ceramic membranes, porous metals and nonwovens.