Zeta potential and particle charge density titration for formulation and quality

assurance of colloidal dispersions

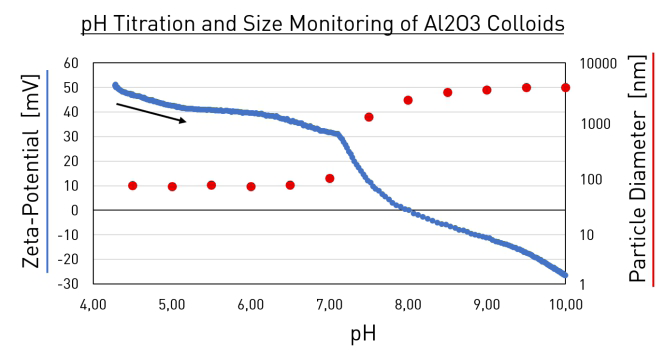

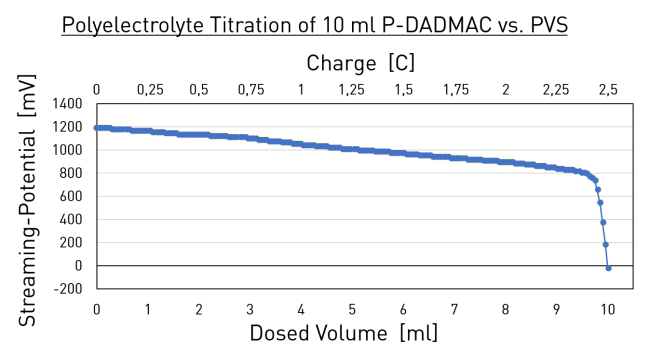

The most important parameters for determining the stability of dispersions are the zeta potential and the particle charge density. Even small changes in these parameters, as they occur in the formulation and preparation of dispersions, can lead to destabilization. The selective determination of the zeta potential on diluted samples allows only vague statements about the influence of the individual process additives on the stability of the formulations. The Stabino® II measures either the zeta or flow potential (streaming current potential). Conductivity, pH value and

temperature are determined simultaneously. In contrast to the commonly used measuring instruments, which are based on an optical measurement of the zeta potential, the Stabino® II can also continuously measure the dispersion stability on concentrated (up to 40 % by volume) and sedimenting (from 0.3 nm to 300 μm) samples during a titration. This allows specific statements to be made about the influence of the individual additives on stability and saves time during formulation. Two integrated dosing pumps allow a fast and precise determination of both the isoelectric point and the particle charge density. In combination with the NANO- flex® II, the particle size distribution can be determined simultaneously during titration.

Method

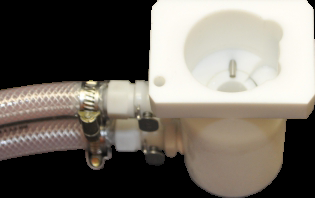

The core of the Stabino II is a cylindrical PTFE measuring cup with an oscillating piston (see figure below).

Charged particles generate an ion shell in polar liquids to balance the charge between the particle surface and the

liquid. This ion cloud can be deformed by a movement of the solvent, resulting in charge separation. The Stabino

generates this charge separation by a liquid flow due to the oscillating motion of the plunger. The particles are

immobilized on the walls of the beaker and the liquid flow causes the charge separation. The level of charge

separation (the zeta or streaming potential) is measured via two electrodes and is an indicator of the stability of the

particles against agglomeration. After appropriate calibration, the measuring signal is output as flow

potential or zeta potential. The titration solutions are added via integrated pumps consisting of two storage

containers. The liquid movement during measurement leads to rapid homogenization during titration and allows

rapid measurements. In addition to zeta potential and titrant volume, from which the particle charge density is

calculated, temperature, pH value and conductivity are also measured.

Applications

The measuring principle of the Stabino enables the stability prediction of dispersions in original concentration. Due to the additional titration possibility, stability ranges and aging processes can be detected very quickly. The influence of the individual additives on the stability can also be determined and optimized during formulation and shortens the

development time. The determination of the isoelectric point and the charge titration are important features in the quality control of products or starting materials and help to select suitable starting materials (such as pigments or additives).

Typical areas of application are for example:

l Printing industry (ink jet inks, flexo, screen

printing), pigments

l Ceramics

l Pharmacy

l Food industry (brewing, beverage technology)

l Coatings

l Materials research (e.g. nanocellulose)

Particle size determination from 0.3 nm to 10 μm with 180° DLS system

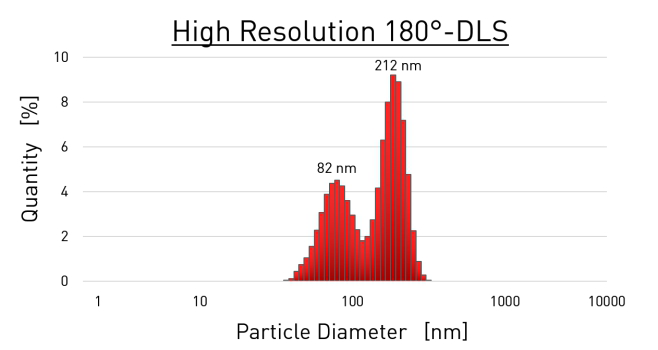

The NANO-flex II 180° DLS system measures particle size distributions of suspensions and emulsions in the range of 0.3 nm to 10 μm and concentrations up to 40 % by volume. The principle of heterodyne 180° backscattering applied here is characterized by its high selectivity in the nm range and a very high resolution; it is also suitable for samples with a wide or multi-modal size distribution. Due to the low penetration depth of the laser light, samples of high concentration are measured without disturbing multiple scattering. Compared to cuvette based systems, many samples can be measured without dilution in the original concentration. The dip-in probe used in the NANO-flex II has a diameter of 5.5 mm and allows a wide range of applications. In conjunction with the IPAS extension, particle size distributions can be measured inline. In combination with the Stabino II, stability ranges and critical coagulation points can be determined.

Applications

For the size determination with the NANO-flex II there are hardly any restrictions, if the viscosity of the sample is

in the Newtonian range. Depending on the refractive index, viscosity and particle shape, particle sizes from

0.3 nm to 10 μm and concentrations up to 40 % by volume can be measured. The flexible and robust measuring

probe is multifunctional, easy to clean and allows measurements in almost all media. Together with the IPAS extension, in-line measurements can be realized.

Typical areas of application for the NANO-flex II are:

l Printing industry (ink jet inks, flexo, screen

printing), pigments

l Ceramics

l Pharmacy

l Food industry (brewing, beverage technology)

l Coatings

l Materials research (e.g. nanocellulose)

The laser is focused into the sample by an dip-in probe with sapphire glass disk. Part of the laser light is reflected

by the sapphire glass. This reference laser light and the light backscattered by the particles interfere with the

detector. The information about the particle size distribution carries the light backscattered by the

particles, the reference laser light acts as optical amplification and increases the signal to noise ratio. The

amplified scattered light signal is converted into a “power spectrum” from which the particle size distribution is

calculated.

Two decisive advantages result from the 180° DLS measuring principle:

>l No multiple scattering due to the low penetration

depth (approx. 50 μm) of the laser light into the

sample.

>l High sensitivity and resolution due to optical

amplification of the measuring signal.

Examples

Stabino® II

NANO-flex® II

IPAS

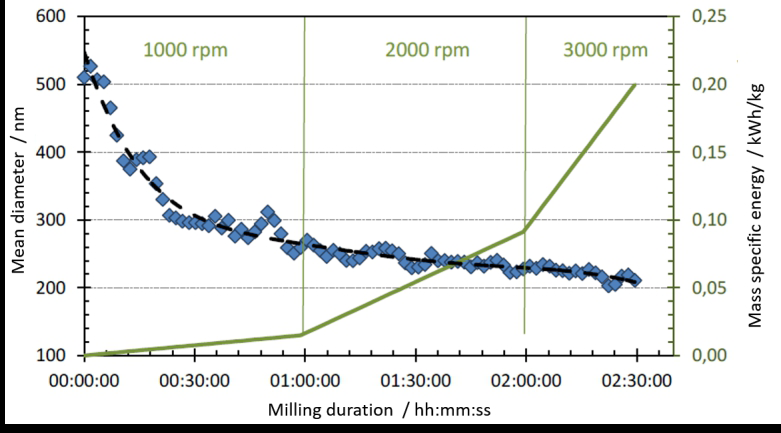

Inline Monitoring of a particle milling process

IPAS

Inline Particle Analysis System – Inline measurements in real time

In many production processes of dispersions, such as printing inks or inkjet inks, there is an increasing need to measure particle size in real time during production. This allows very good control over top-down and bottom-up processes as well as energy- and time-efficient product manufacturing. On the other hand, mixing during the

manufacturing process prevents direct measurement in the medium. The IPAS solves this problem by means of an encapsulated measuring chamber which can be filled and rinsed automatically with the sample from the process by means of an impeller. The measuring probe of the IPAS is integrated into the measuring head of the . The ® NANO-flex II coupling with process control units enables fully automatic control and monitoring of the process sequence.

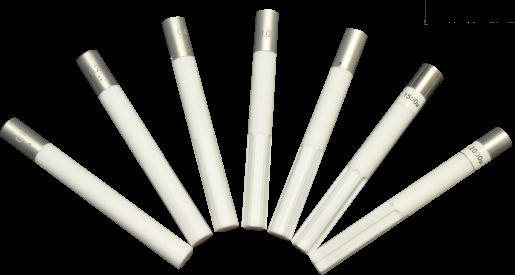

Accessories

10 mL

including piston

-black-

from 0°C to 90°C

l 200 μm

l 400 μm

l 1000 μm

l 2000 μm conical